Constructed in the 1920s, the Museum’s glass casket (2001.4.234) weighs between 400 and 500 pounds. The type of pressing machine that was used to make it weighed approximately 31,000 lbs. The American Glass Casket Company claimed that their casket press, measuring 13 feet tall, 25 feet long with a width of 5 feet was the largest glass press in the world in 1921. Glass coffins, which were cushioned with yards of fabric, were not meant to display the body but rather to hygienically protect it from the elements.

Glass was being used in casket construction as early as the 1850s and patents are seen starting in 1859 for glass caskets, but DeCamp did not patent his two piece adult sized casket until 1915. In 1921, the American Glass Casket Company owned “the exclusive right to manufacture and sell the DeCamp Glass Casket in the states of Oklahoma, Texas, Arkansas and New Mexico and [was] the parent-producing company in the making of this glass casket under the DeCamp patents” ([Glass casket catalog] Bib # 74869, page 12) while other plants each had their own respective territories.

Of the trade catalogs in the Rakow Library’s collection, one on glass caskets is fully viewable online. The catalog for Crystal Glass Casket Company, Washington, DC describes their caskets as “hermetically sealed by applying a composition which renders the casket air-tight, water-tight, vermin-proof and absolutely sanitary, thus assuring a perfect burial receptacle” (page 7). The makers explain that the strength of glass is greater than other materials commonly used in coffin or casket production including woods and metals. The catalog contains interesting photographs documenting the production facilities and can be seen online here.

DeCamp trimming room, Cut No. 13 from Bib 52588 – DeCamp Consolidated Glass Casket Co., Muskogee, OK, USA.

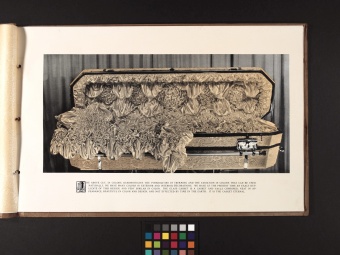

After the glass bowl and lid of the casket were pressed, they had to be annealed for approximately six hours to relieve stress from the glass. Dealing with pieces of such a large size, cracks were often a problem. In the trimming room at the factory, felt or fabric was applied to the outside of the glass to prevent the metal handles from coming in direct contact with the glass surface. Silk or brocade was used to decorate the caskets as can be seen in the photos above and below. Small caskets were used as samples since they were easier to produce. It is unknown how many full size caskets were produced, but today only two 6′ 3″ caskets remain intact, both in museum collections.

Glass casket from Bib 45886 – DeCamp Consolidated Glass Casket Co., Muskogee, OK, USA.

Many questions still surround the history of glass casket production. Some accounts relate that certain factories did not produce any full size glass caskets at all, but were merely a front to attract investors. In 1923, several company representatives were indicted and charged with conspiracy in connection to the sale of company stock. Most investors saw no returns and bankruptcy came for companies rather quickly. For further information, or to view additional catalogs from other firms, including the DeCamp Consolidated Glass Casket Company, contact or visit The Rakow Research Library.

The Rakow Research Library is open from 9:00 a.m. – 5:00 p.m., Monday – Friday

Telephone: 607.438.5300 | Email (general inquiries): rakow@cmog.org

Explore the collection online using the classic catalog or the Library’s collection browser.

Pingback: The Glass Casket | Blogging by Amy De Simone